HiPoint Ag Process

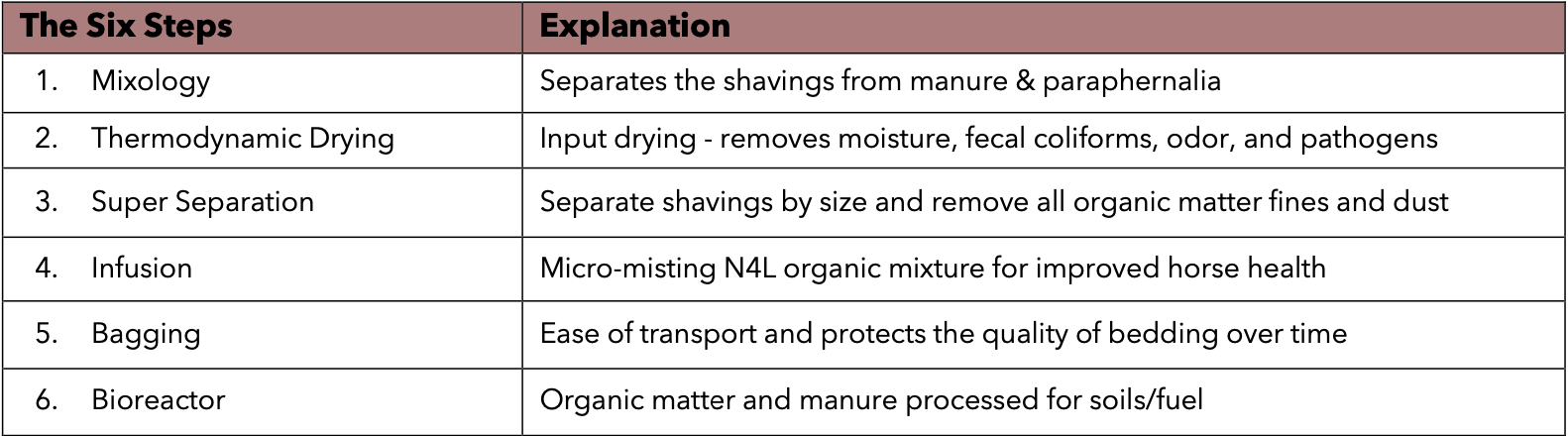

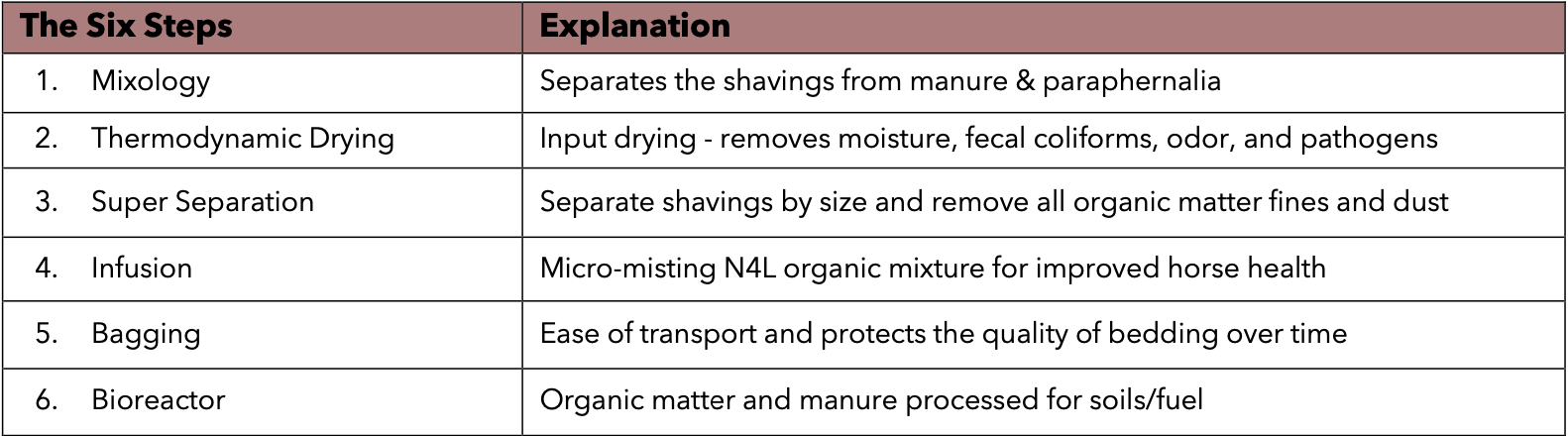

Revolutionary 6 Step Process

HiPoint Ag Process

RevolUTIOnary 6-Step Process

What is the HiPoint Process

What is the HiPoint Process

Patent Pending Innovation.

The Equipment

HiPoint’s manufacturing partners are highly reputable in equipment design for separation, drying, and bagging. The equipment has been available in the industry for years; HiPoint has configured it in a new, unique process.

- Drying with low to no emission

- Separating shavings from SRW without damaging the wood fibre integrity

- Carbon filters and ozone to remove malodour

- Custom integrations for full automation

The Equipment

HiPoint’s manufacturing partners are highly reputable in equipment design for separation, drying, and bagging. The equipment has been available in the industry for years; HiPoint has configured it in a new, unique process.

- Drying with low to no emission

- Separating shavings from SRW without damaging the wood fibre integrity

- Carbon filters and ozone to remove malodor

- Custom integrations for full automation

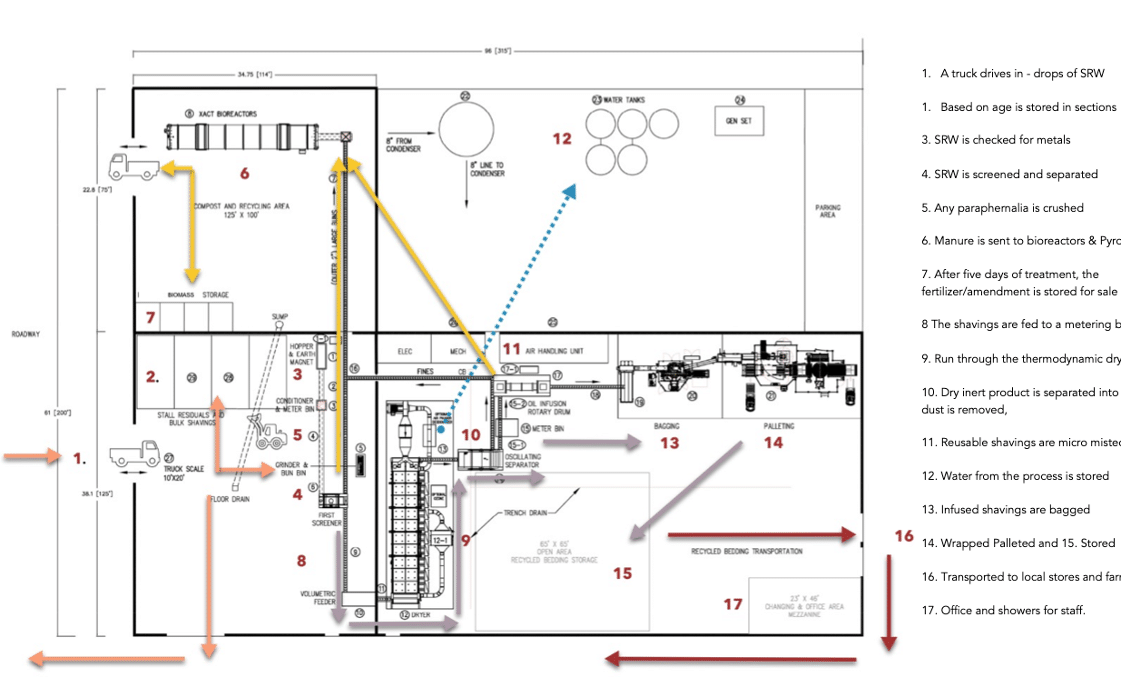

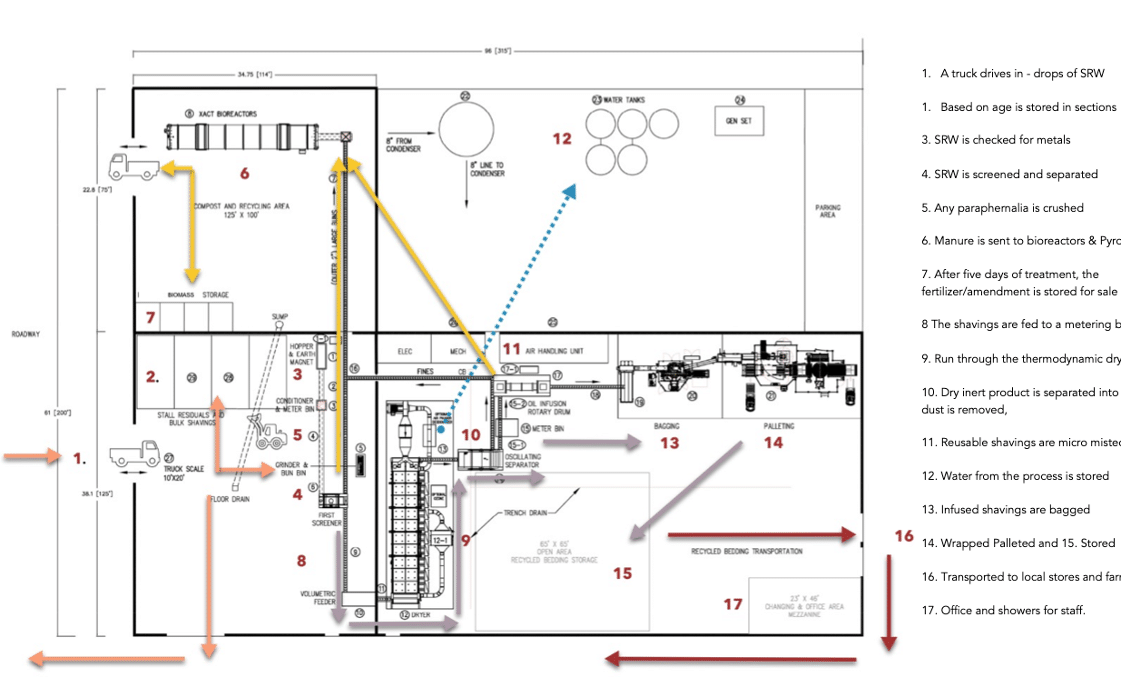

6-Step Closed Loop Environmental Recycling

The six-step process, which includes super-screen separation, thermo-dynamic drying, and the infusion of organic oils, allows the bedding to be recycled in multiple cycles. From this single waste stream (SRW), HiPoint repurposes shavings, manure, fines, and reclaims wastewater. HiPoint does this while supporting waste management best practices and biosecurity procedures.

6-Step Closed Loop Environmental Recycling

The six-step process, which includes super-screen separation, thermo-dynamic drying, and the infusion of organic oils, allows the bedding to be recycled in multiple cycles. From this single waste stream (SRW), HiPoint repurposes shavings, manure, fines, and reclaims wastewater. HiPoint does this while supporting waste management best practices and biosecurity procedures.

HiPoint Process In-depth Overview

HiPoint Ag and its partners recycle equine stall residuals naturally, without chemicals, through a six-step process. The process is biosecure, best practices, and environmentally friendly. The HPAB Facilities combine wood shaving recycling, water reclamation, and biomass byproducts. The process produces clean and competitively priced recycled bedding for equestrian stalls. The bedding can be recycled multiple times. The process is safe for horses, riders, and the environment. The spent horse shavings are taken to bio-secure Facilities and routed through a six-step process. The buildings are humidity and odor controlled and designed for equine aesthetics. Facilities hold from 18,000 to 59,000 tons of waste per year.

We ensure consistent quality through batch testing and lab testing from approved labs.

STEP 1 – Mixing and Separating the raw stall residuals. The stall residuals are mixed and separated based on specification. The manure buns are treated separately while the unusable items are separated, crushed, and disposed of.

STEP 2: Thermodynamic Drying and Water Reclamation. The shavings are dried through a thermodynamic system that removes harmful components and turns the moisture into water, which is then used for cleaning, irrigation, or drainage. Low ozone and bicarbonate of soda help to reduce odor and air pollution.

STEP 3: Super Screen Separation to Customer need. We process dried, cleaned, and inert bedding fibers through a Super Screen to remove organic matter and separate flakes based on customer needs.

STEP 4 - Proprietary Infusion Tank to Protect Horse & Rider. Our proprietary infusion tank covers the bedding with a safe and natural compound that can help heal horses and improve barn conditions.

STEP 5: Quiet Fully Automated Baler. Our fully automated baler produces multiple bags per minute for efficient operation.

STEP 6: Bioreactor for Efficient Faster Biomass. We process manure and organic matter fines in a covered bioreactor to become inert and cured for energy and gas production or as a soil amendment. Our bioreactor is faster than traditional composting methods, taking only 5 days to break down wood shavings.

The HiPoint Ag Process is the most efficient, fully automated, digitally tracked Facility to recycle wood shavings - great for the horse industry and the environment.

HiPoint Process In-depth Overview

HiPoint Ag and its partners recycle equine stall residuals naturally, without chemicals, through a six-step process. The process is biosecure, best practices, and environmentally friendly. The HPAB Facilities combine wood shaving recycling, water reclamation, and biomass byproducts. The process produces clean and competitively priced recycled bedding for equestrian stalls. The bedding can be recycled multiple times. The process is safe for horses, riders, and the environment. The spent horse shavings are taken to bio-secure Facilities and routed through a six-step process. The buildings are humidity and odor controlled and designed for equine aesthetics. Facilities hold from 18,000 to 59,000 tons of waste per year.

We ensure consistent quality through batch testing and lab testing from approved labs.

STEP 1 – Mixing and Separating the raw stall residuals.

The stall residuals are mixed and separated based on specification. The manure buns are treated separately while the unusable items are separated, crushed, and disposed of.

STEP 2: Thermodynamic Drying and Water Reclamation

The shavings are dried through a thermodynamic system that removes harmful components and turns the moisture into water, which is then used for cleaning, irrigation, or drainage. Low ozone and bicarbonate of soda help to reduce odor and air pollution.

STEP 3: Super Screen Separation to Customer need

We process dried, cleaned, and inert bedding fibers through a Super Screen to remove organic matter and separate flakes based on customer needs.

STEP 4 - Proprietary Infusion Tank to Protect Horse & Rider

Our proprietary infusion tank covers the bedding with a safe and natural compound that can help heal horses and improve barn conditions.

STEP 5: Quiet Fully Automated Baler

Our fully automated baler produces multiple bags per minute for efficient operation.

STEP 6: Bioreactor for Efficient Faster Biomass

We process manure and organic matter fines in a covered bioreactor to become inert and cured for energy and gas production or as a soil amendment. Our bioreactor is faster than traditional composting methods, taking only 5 days to break down wood shavings.

The HiPoint Ag Process is the most efficient, fully automated, digitally tracked Facility to recycle wood shavings - great for the horse industry and the environment.